当前你的浏览器版本过低,网站已在兼容模式下运行,兼容模式仅提供最小功能支持,网站样式可能显示不正常。

请尽快升级浏览器以体验网站在线编辑、在线运行等功能。

2107:Gear Profiles

题目描述

The Dynamic Gears Company is developing a new program to manufacture gears based on a master gear. The first step consists on making measurements of the master gear using the T-500 machine. This machine creates a file with coordinates of different points on one of the gear's tooth.

The Dynamic Gears Company is developing a new program to manufacture gears based on a master gear. The first step consists on making measurements of the master gear using the T-500 machine. This machine creates a file with coordinates of different points on one of the gear's tooth.

The T-500 machine finds the coordinates of several points on the surface of one of the tooth's face. These points represent a grid that defines the entire surface (as seen on the image). The T-500 machine measures X points on the tooth from top to bottom, then it moves towards the inside to read again X points. This sweeping is done Y times until the gear is complete. The final result of the T-500 machine is a file with a consecutive list of X*Y points.

The Gear Technology Department has to develop a program capable of calculating the geometry of the tooth based on the grid of points, and generate the instructions for the machine that will cut the gears. After analyzing the problem it was decided that the Normal value of several points has to be calculated so that the cutting machine knows how to generate the gear.

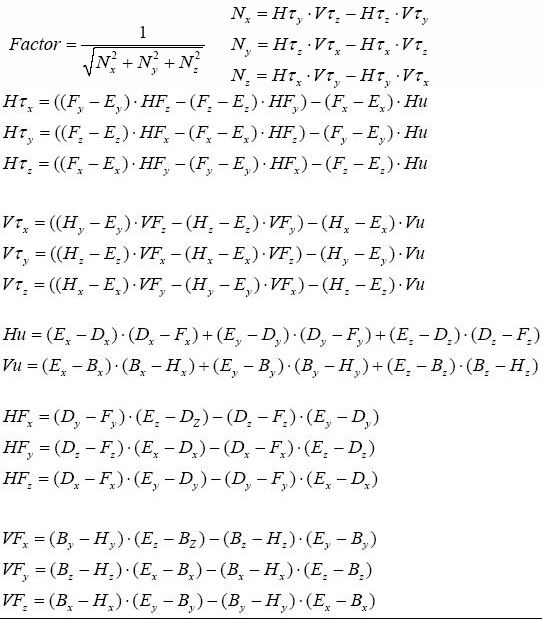

To be able to calculate the Normal value, 9 points from the grid have to be considered together (as seen on the diagram). For example, if the T-500 machine read 5 points from top to bottom and 3 columns from left to right, points A, D, and G come from the first three points the T-500 machine read. Points B, E, and H come from points 6, 7, and 8. Points C, F, and I come from points 11, 12, and 13. The small 9-points grid contains the required values to calculate the Normal value using the following formula:

To be able to calculate the Normal value, 9 points from the grid have to be considered together (as seen on the diagram). For example, if the T-500 machine read 5 points from top to bottom and 3 columns from left to right, points A, D, and G come from the first three points the T-500 machine read. Points B, E, and H come from points 6, 7, and 8. Points C, F, and I come from points 11, 12, and 13. The small 9-points grid contains the required values to calculate the Normal value using the following formula:

Normx=Nx*Factor

Normy=Ny*Factor

Normz=Nz*Factor

Where

The program to develop must go through all points on the grid that the T-500 machine generated, using the 9-points grid, moving from top to bottom first, and then from left to right. The first 9-points grid, therefore, uses points A=1, D=2, G=3, B=6, E=7, H=8, C=11, F=12, and I=13; the second 9-points grid uses points A=2, D=3, G=4, B=7, E=8, H=9, C=12, F=13, and I=14; etc.

输入解释

The input represents the file generated by the T-500 machine with only one case. The first line contains two positive integers X (3 <= X <= 50) and Y (3 <= Y <= 50). X is the number of points read from top to bottom, and Y is the number of columns read from left to right.

All the following lines have 3 floating-point numbers: x , y , and z . The three values represent the coordinates of the measured point in the Cartesian plane. Each number has a maximum of 4 decimals.

All the following lines have 3 floating-point numbers: x , y , and z . The three values represent the coordinates of the measured point in the Cartesian plane. Each number has a maximum of 4 decimals.

输出解释

The output must contain on the first line the total number of points contained on the input.

Starting on the second line, the Normx , Normy and Normz values from all calculated Normal values must be printed, one line for each calculation. The values must be floating-point numbers with 4 decimals, separated by single blank space.

Starting on the second line, the Normx , Normy and Normz values from all calculated Normal values must be printed, one line for each calculation. The values must be floating-point numbers with 4 decimals, separated by single blank space.

输入样例

5 3 -36.9469 225.1665 150 -36.7819 226.3999 150 -36.5822 227.7063 150 -36.3451 229.0841 150 -36.0678 230.5327 150 -35.7464 232.0432 150 -34.3768 237.1574 150 -33.9837 238.7979 150 -33.5259 240.2806 150 -33.0456 241.757 150 -32.5119 243.3183 150 -31.9384 244.9173 150 -32.8032 225.8074 135 -32.6156 227.0375 135 -32.392 228.34 135

输出样例

15 0.0000 0.0000 1.0000 0.9423 -0.2594 0.2117 0.9373 -0.2972 0.1819

最后修改于 2020-10-29T06:23:32+00:00 由爬虫自动更新

共提交 0 次

通过率 --%

| 时间上限 | 内存上限 |

| 1000 | 30000 |

登陆或注册以提交代码